Fluid transfer systems are essential in various industries, from chemical processing to food production. Selecting the right components for these systems ensures safe and efficient operations. Two commonly used components for fluid transfers are the pressure vacuum valve and the butterfly valve.

Pressure Vacuum Valve (PVV):

Pressure vacuum valves, often referred to as PVVs, are vital components in fluid transfer systems. They are crucial in maintaining optimal pressure and preventing vacuum formation within tanks or pipelines. Here’s a closer look at their features and applications:

- Pressure Relief: PVVs prevent overpressure situations, which can occur due to thermal expansion or other factors, by releasing excess pressure to maintain system integrity.

- Vacuum Protection: These valves also protect against vacuum formation, which can cause tanks to collapse or lead to pump cavitation.

- Applications: PVVs are commonly used in storage tanks, pipelines, and tanker trucks for liquids like chemicals, petroleum, and pharmaceutical manufacturing.

Butterfly Valve:

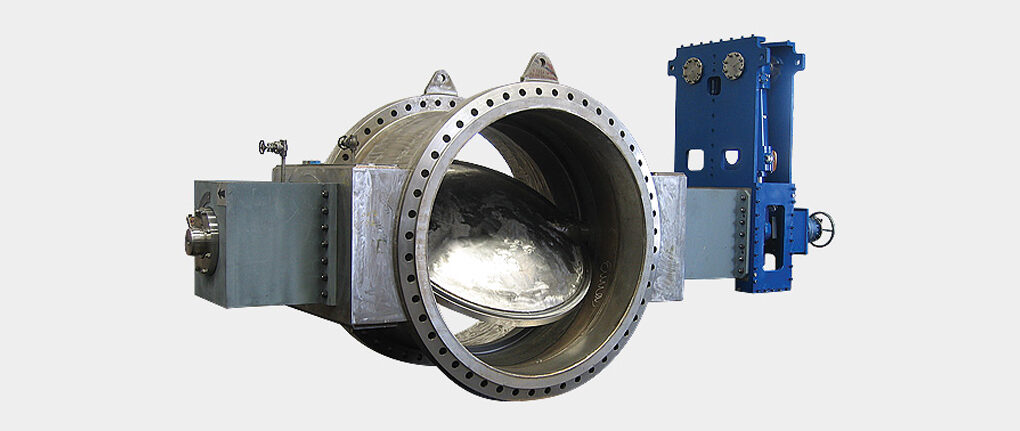

Butterfly valves are another crucial component in fluid transfer systems, primarily designed to regulate fluid flow. Their distinctive disc-like shape allows for precise control overflow rates. Here’s what you need to know about butterfly valves:

- Flow Control: Butterfly valves are excellent for throttling the flow of fluids, making them ideal for applications where flow rate adjustment is necessary.

- Quick Operation: They operate swiftly, making them a preferred choice when rapid flow adjustments are required.

- Applications: Butterfly valves are commonly used in water treatment plants, HVAC systems, and industries where precise flow control is essential, such as the beverage and pharmaceutical industries.

Choosing the Right Component:

The choice between a pressure vacuum valve and a butterfly valve depends on your specific application:

- Pressure Management: If your primary concern is maintaining pressure and preventing vacuum formation, a pressure vacuum valve is the way to go.

- Flow Control:A butterfly valve is the better choice for applications requiring precise flow rate adjustments.

Pressure vacuum and butterfly valves play distinct but equally important roles in fluid transfer systems. Hence, understanding their functions and applications will help you make an informed decision when selecting components for your fluid transfer system. Ensure efficiency, safety, and optimal performance as you explore more about these components from Treloar.