The Key Functions of a PCB Board Explained Simply

Every electronic gadget, from your phone to your fridge, depends on one unsung hero: the Printed Circuit Board, or PCB. It might look like a flat green plate with a web of copper lines, but beneath that tidy design lies the foundation of modern electronics. To understand why this small board matters, it helps to look at its key functions and how each one keeps devices running smoothly. For many businesses involved in PCB manufacturing in Singapore, this foundation is where precision meets practicality.

Electrical Connection and Signal Flow

A PCB acts as the main road system for electricity. The copper traces etched onto its surface connect every component, ensuring that current flows to the right places at the right times. Without it, circuits would rely on messy wires tangled across the device, making both assembly and repair nearly impossible.

In a PCB board in Singapore, engineers design these traces carefully to prevent interference between signals. They decide which layers handle power and which carry data, arranging them like lanes on a motorway to avoid traffic jams of electrons. When done correctly, this layout ensures each part of the device communicates effectively without electrical noise or delay.

Mechanical Support and Organisation

Besides managing current, the PCB provides a strong, stable base for all components. Resistors, capacitors, and chips are mounted firmly on its surface, allowing the device to survive movement, vibration, and temperature changes. The rigid structure ensures that even in compact gadgets, every piece stays exactly where it should.

Manufacturers specialising in PCB manufacturing in Singapore use materials like FR-4, a glass-reinforced epoxy laminate, to maintain strength and insulation. It’s a material tough enough to handle heat during soldering while remaining lightweight and reliable. Without this backbone, even the smartest circuits would crumble under stress.

Power Distribution Across Components

A PCB acts as a power manager. Different sections of the board deliver the exact voltage each component needs. Power traces act as arteries, distributing energy evenly throughout the system. If the flow isn’t managed properly, components can overheat, underperform, or fail altogether.

Designers of a PCB board in Singapore calculate current capacity and copper thickness carefully to prevent such issues. They also introduce ground planes and decoupling capacitors to maintain stability. It’s a quiet yet vital balancing act, ensuring that power delivery remains steady without drawing unnecessary heat or energy.

Insulation and Safety Functions

Electrical insulation is one of the unsung functions of a PCB. It separates conductive paths, preventing unwanted connections and protecting the board from short circuits. The substrate material provides both electrical isolation and mechanical stability, keeping the device safe from internal sparks or overloads.

PCB manufacturing in Singapore treats insulation as a core safety measure. They ensure the board’s dielectric layers meet strict standards for voltage resistance and durability. A well-insulated PCB is like a careful electrician, always keeping high-voltage lines apart from delicate signal routes.

Thermal Management and Heat Control

Electronic components naturally produce heat, and without proper management, that heat can cause damage or reduce performance. PCBs play a critical role in keeping things cool. They use copper areas, thermal vias, and heat sinks to spread and release heat efficiently. The goal is simple: prevent localised hotspots that could harm the board or surrounding components.

Design teams working on a PCB board in Singapore often use simulation tools to predict how heat moves through the layout. These insights help them position components wisely and choose materials with proper thermal conductivity. Effective thermal design extends the life of both the board and the device it powers.

Structural Layers and Multilayer Design

Modern PCBs often feature multiple layers to support complex circuits within compact devices. Each layer serves a purpose: signal routing, grounding, or power distribution. These layers are laminated together with precision to create a single, cohesive structure.

In high-performance applications, such as communications or industrial control, manufacturers involved in PCB manufacturing in Singapore rely on tight layer alignment and strict process control. The result is a stable, efficient board that balances electrical function with mechanical strength. The multilayer design turns complexity into clarity, keeping all signals in sync.

Quality Assurance Through Testing and Inspection

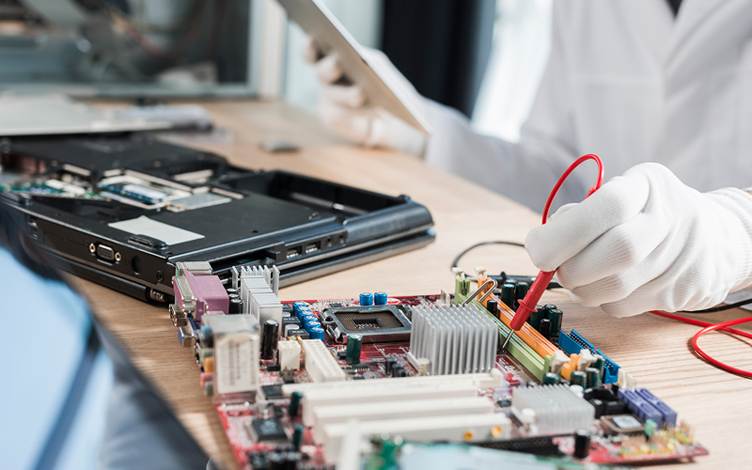

Before a PCB is approved for assembly, it goes through a series of checks known as testing and inspection. These steps verify that all connections are accurate, traces are clean, and there are no hidden defects. Some tests involve visual inspection under magnification, while others use automated systems that check for continuity, resistance, or short circuits.

These tests might seem routine, but they protect both the manufacturer and the end user from malfunction. Each inspection confirms that the PCB can withstand the stresses of soldering, component placement, and operation. Quality assurance ensures that what leaves the production floor works as intended the first time.

The Silent Architect of Modern Devices

The PCB may not light up, make sound, or move, but every device depends on its quiet efficiency. It connects, supports, powers, and protects. Its balance of structure and function allows engineers to bring complex ideas to life without a mess of wires or bulky components.

Understanding these core roles reveals why the PCB is essential to every piece of technology we rely on daily. Contact MPN Tech to collaborate with experts in PCB manufacturing in Singapore who ensure your designs stay functional, reliable, and built to last.